Infrared heaters deliver significantly more radiant heat than industry-standard models.

Let’s review this in more detail.

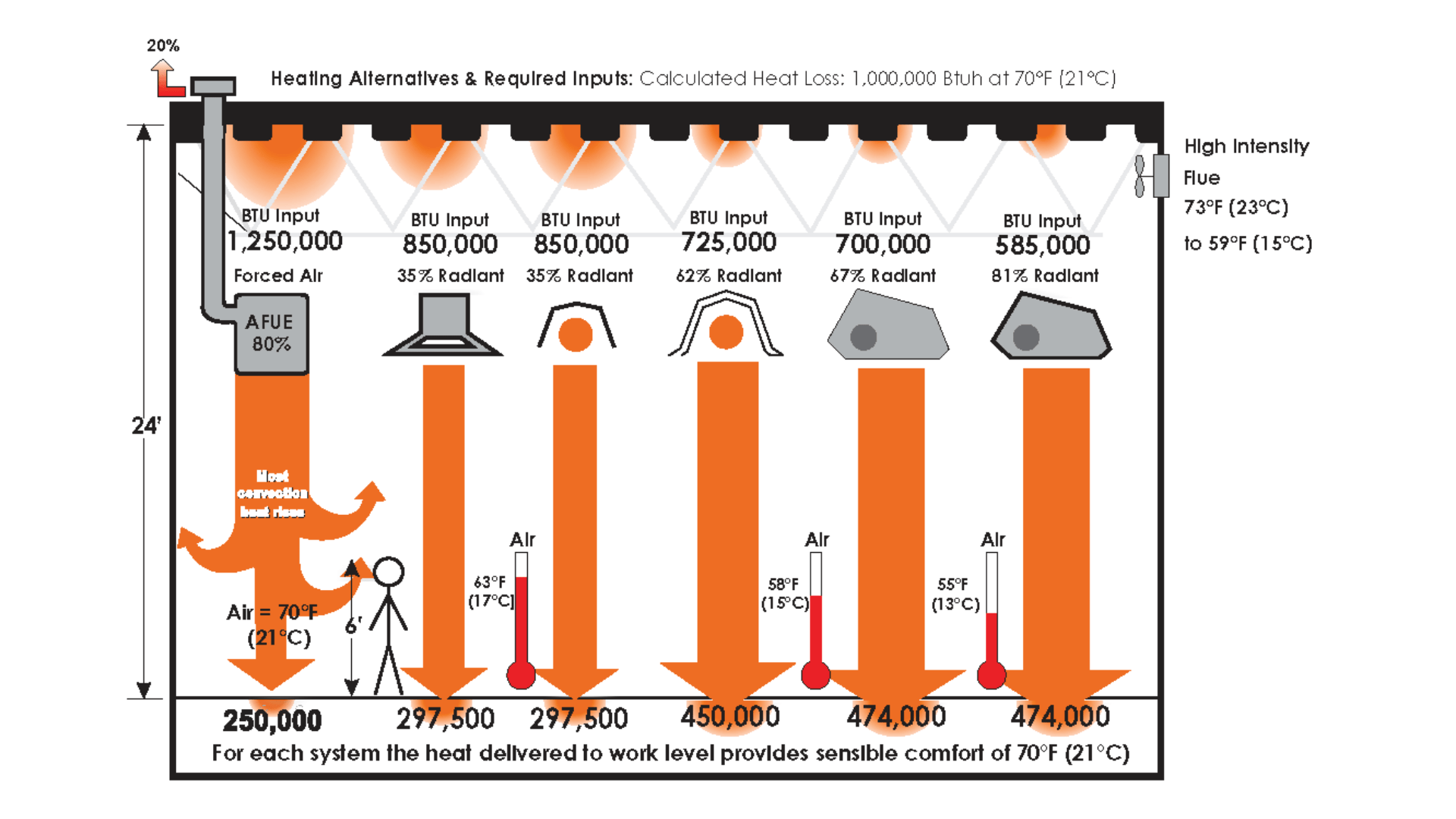

Infrared heating vs. Forced air heating

The above image shows the difference between Infrared heaters and Force Air and also depicts the benefits of high efficiencies within an IR heater product lineup.

Typically forced air systems with 80% AFUE ratings will require about 20% more in BTU input than the heat loss calculation.

Furthermore, with heat rising (in air systems) and standard convection losses, we may only see about 20% of that input at the floor level.

As we move to the right, and change to Infrared technology, we can remove 15% off the heat loss calculation based on ASHRAE Handbook – Fundamentals (Chapter 17 and Chapter 18).

Based on that calculation, the input BTUs are reduced, allowing for a smaller Infrared heater.

Knowing the radiant efficiency of the IR heater, we can estimate the achievable BTU at the floor.

Some high-intensity ceramic IR heaters have very high radiant efficiencies (like 81%) and thus will see more BTUs at the floor level.

With increasing Radiant efficiency, you can further reduce the BTU input, which yields lower fuel consumption.

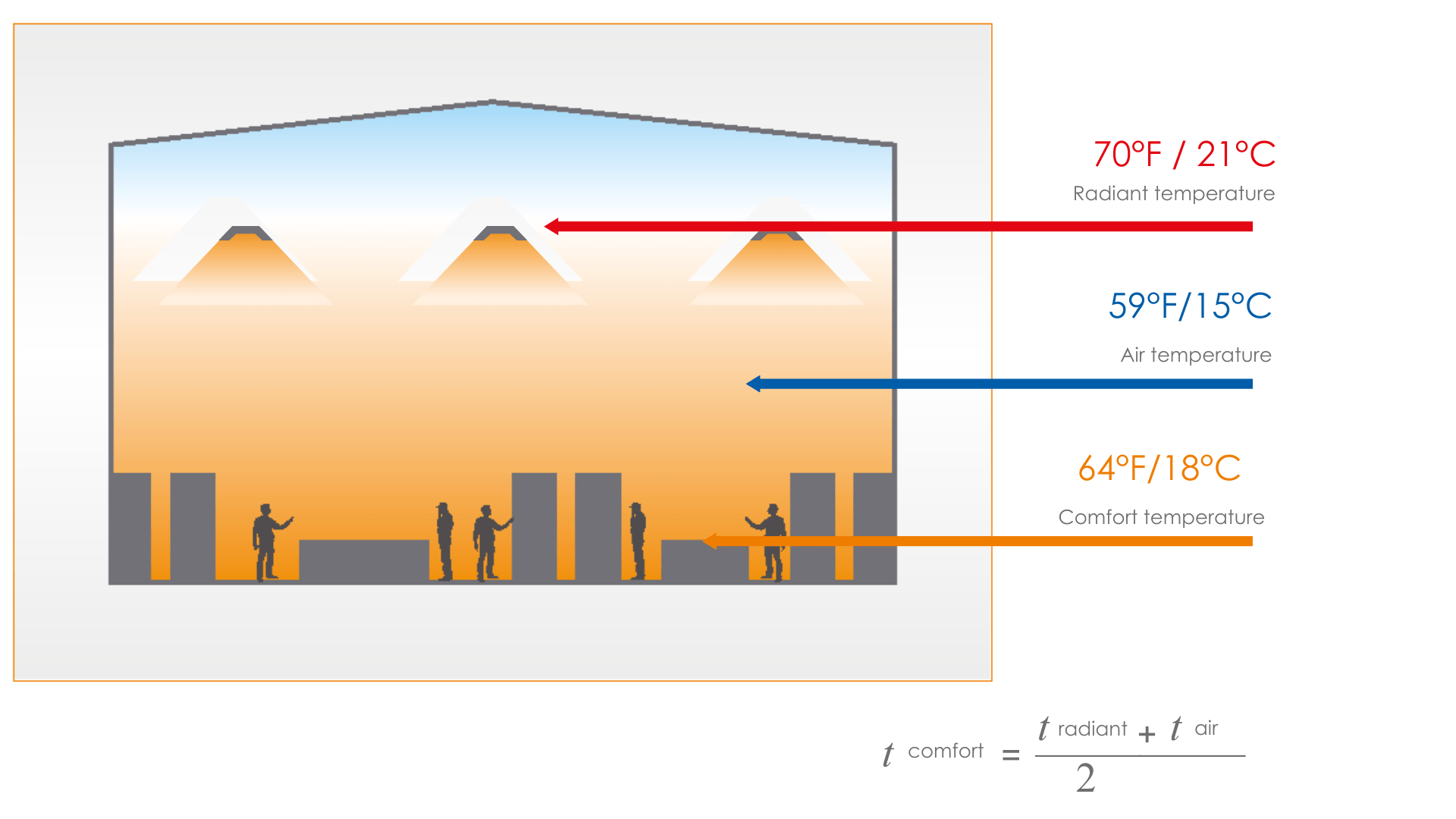

Since we are talking about Infrared heating, we must look at Comfort temperature (the average of Radiant and Air temperatures). Since radiant efficiency is increasing, we are effectively increasing the radiant temperature. If we are to maintain a constant Comfort temperature, we can reduce the air temperature.

Essentially, this has two positive points:

1. If we have supplemental heat (produced by air), we can reduce the Air temperature, thus saving energy. Consider it a setback on the heating side.

2. The IR system can effectively provide desired Comfort temperatures at lower Air temperatures. This envelope gives customers peace of mind knowing their IR system at very different air temperatures.

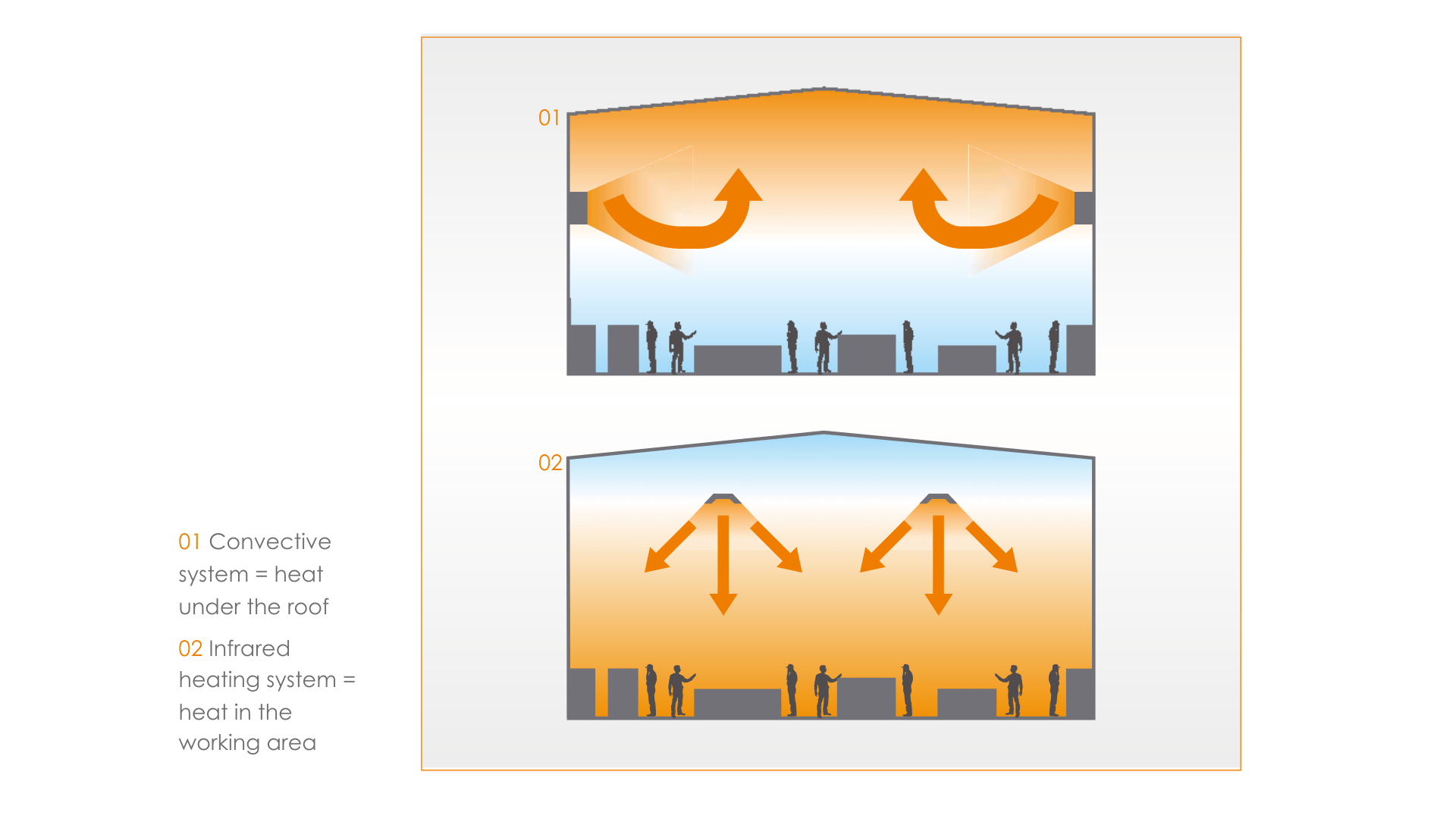

Avoiding hot air stratification below the ceiling.

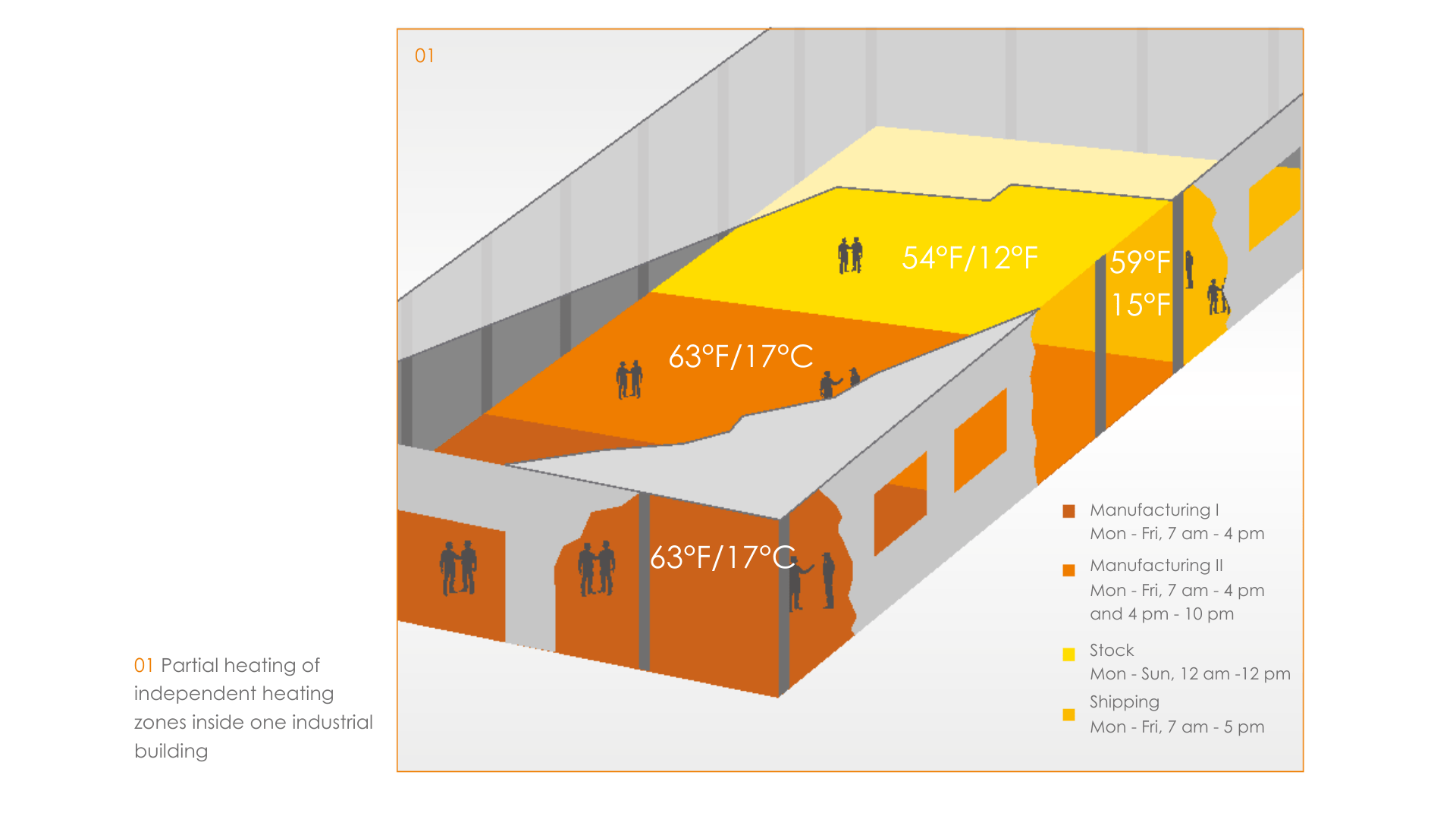

We all know that warm air rises (figure 01). As the molecules in the air are heated, they move apart and expand. And since there is more space between these molecules, the air is less dense, thus causing it to lift upward. But what about space that has high ceilings? We know it would require more effort and energy to force that warm air to the ground.

Then there’s the work to ensure this is continuous and uniform while attempting to maintain the performance and efficiency of a system.

Ultimately, there will be a stratification of temperatures within the space. These are issues with forced air systems.

With infrared technology, we are heating objects, not the space. The technology built into the heaters produces the infrared wave and directs that wave to the objects below; personnel, product, and the floor (figure 02). This is done regardless of the medium between (the air), just like the sun heating the earth, with the vacuum of space in between.

Infrared radiation – efficient heating.

The result is a much more uniform heat distribution in terms of elevation. The comfort temperature can be measured by taking the average of the radiant temperature and air temperature. More efficient infrared systems can produce greater radiant temperatures. In that case, we can lower our air temperature.

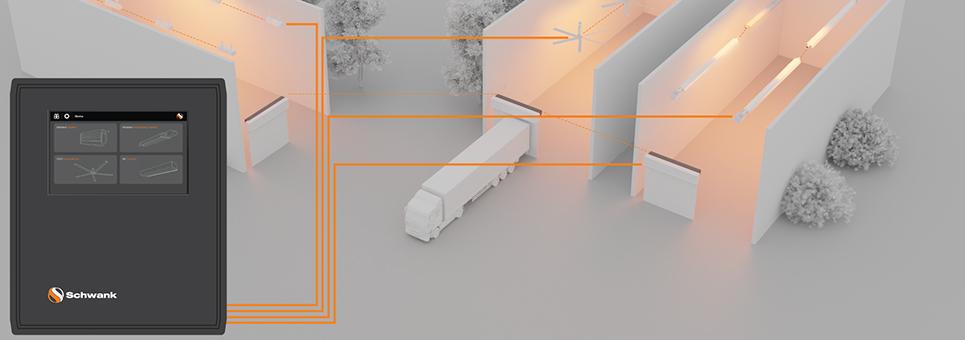

Heat only at the time and in the zone needed.

By using Infrared technology to heat large open spaces (with no walls or partitions), you can also zone allocate and not worry about heat being ‘bleeding’ into another area. With heating the air, there is a possibility of that air moving from one space to another, especially if those spaces are set at different temperatures.

This doesn’t happen with IR heating. You can conveniently have a lower temperature setpoint for storage areas and higher temperatures for a more comfortable space that is occupied by personnel—the new Schwank.ONE controller has the ability to zone allocate and schedule when the IR units can come to operate.

To download a PDF version of the above images, select the links below:

Watch this explainer video on the benefits of using infrared heat.