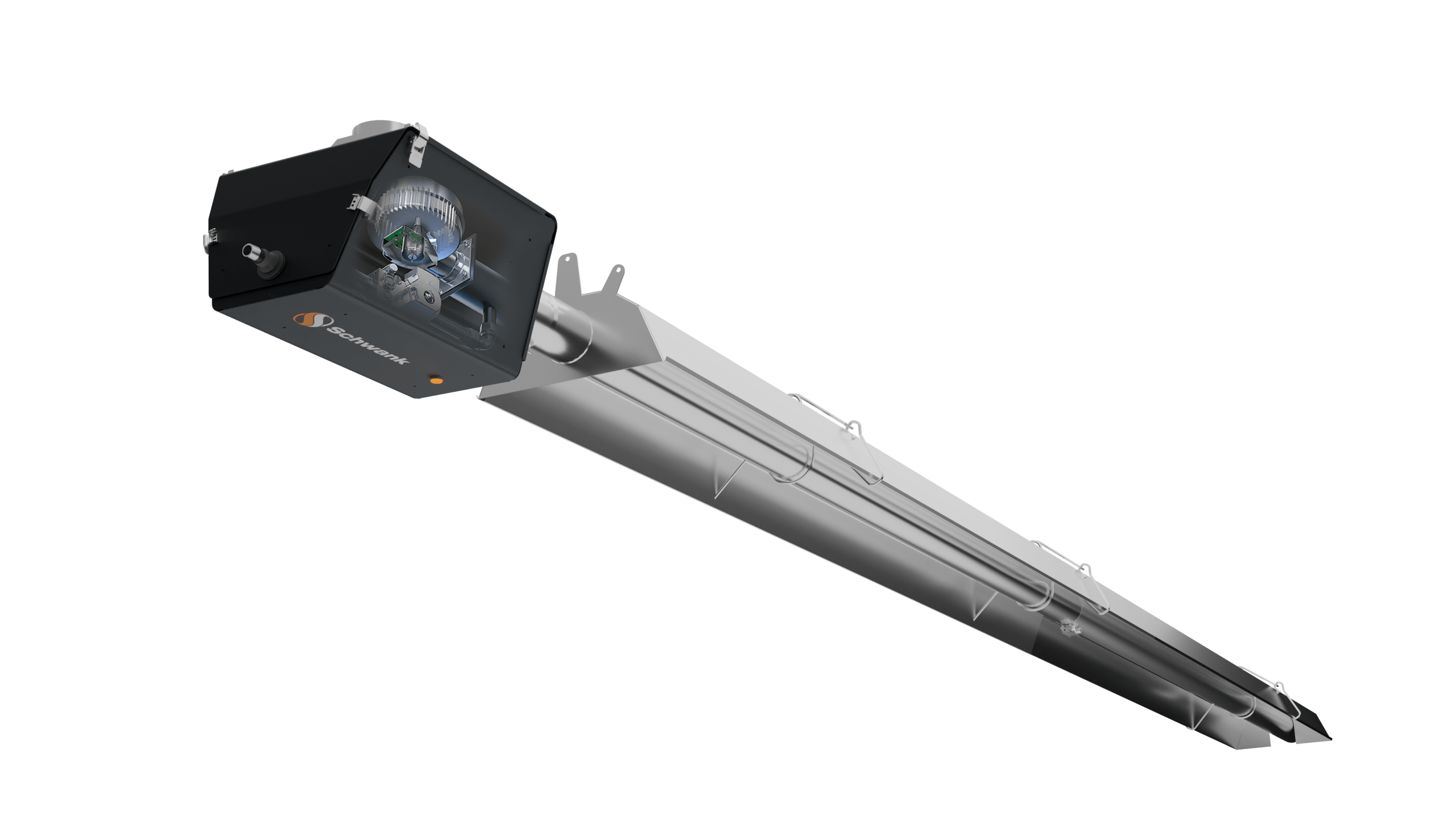

Products / Tube Heaters / superTube Extreme

superTube® Extreme Series

Extreme weather, extreme conditions and extreme environments

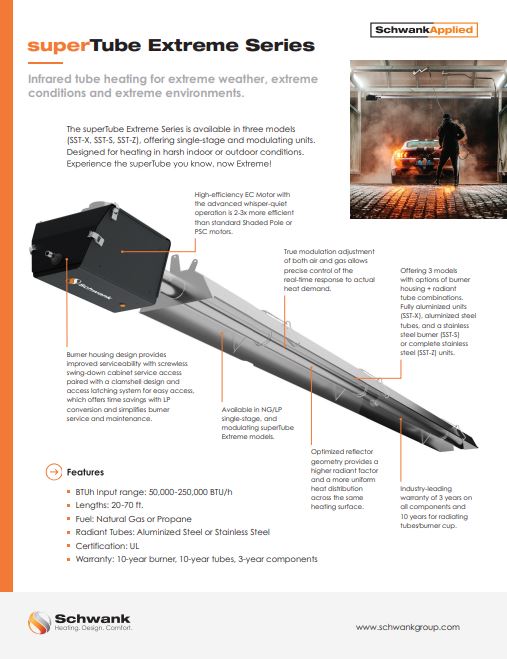

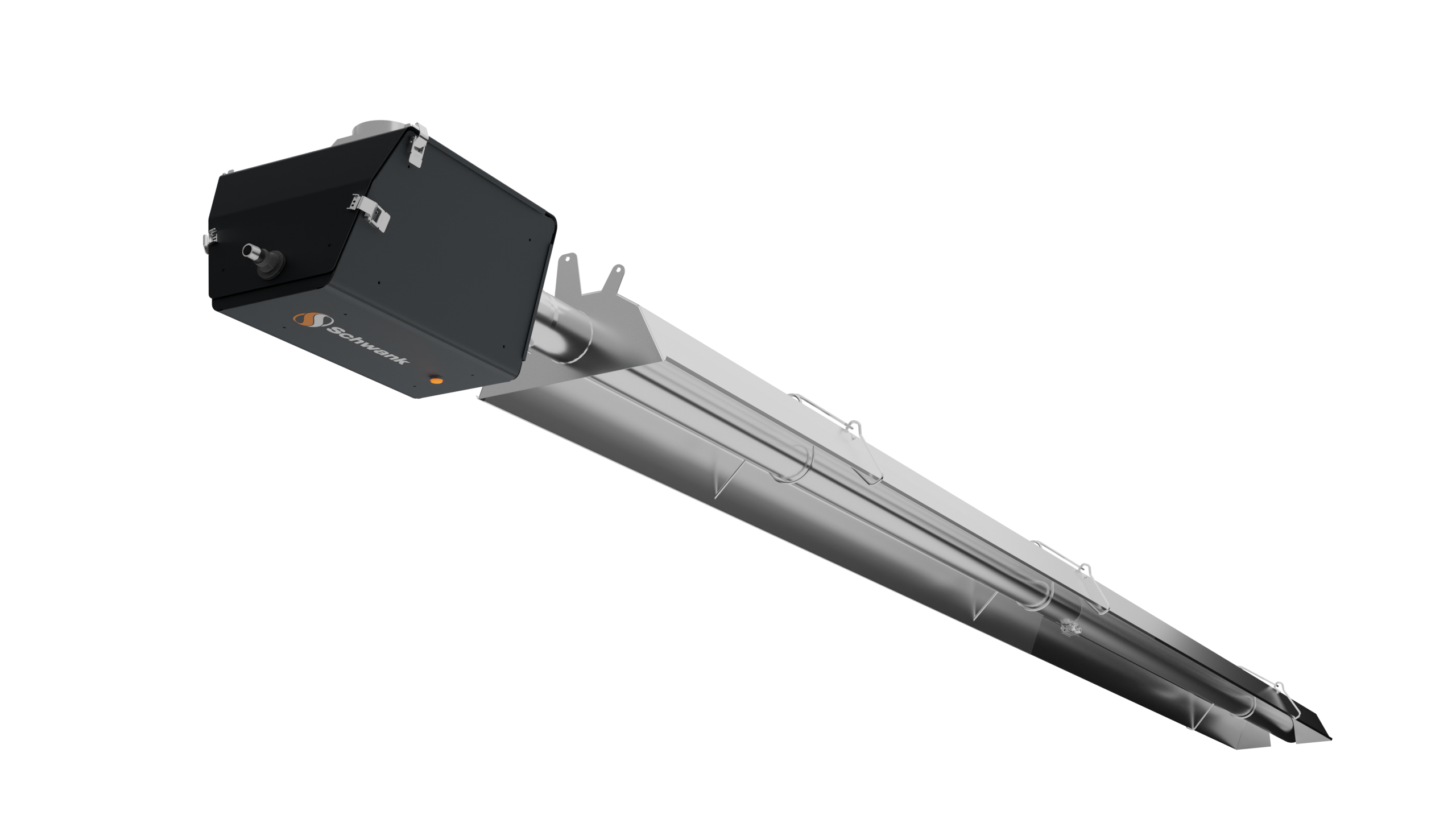

Designed for heating in harsh indoor or outdoor conditions. Experience the newest technology in infrared radiant tube heaters–superTube Extreme Series is available in three models (SST-X, SST-S, SST-Z), offering single-stage and “true” modulating units.

Applications

- Outdoor patios

- Outdoor coastal regions

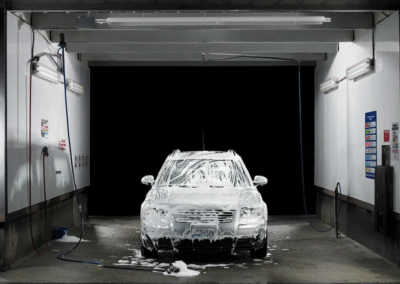

- Car wash / wash bay

- Food service

- Train bay

- Wet, damp, extreme conditions

Video

Introducing Schwank superTube® Extreme Series—An Extreme Advancement in Infrared Heating. Hear from the same engineers who introduced the superTube SST Series to North America! (Watch time 3.40 min)Video

Listen in as our Schwank R&D Team shares the Extreme wet condition testing approach to developing the Schwank superTube Extreme tube heater. (Watch time 0.54 min)superTube Extreme highlights

Be adventurous – infrared heating in extreme applications

Available in “true” modulating and single-stage, the superTube Extreme Series range from 20,000 to 250,000 [BTUhs] and are 20’ to 80’ in length, it is easy to install and maintain. Offering 3 models with options of burner housing + radiant tube combinations – fully aluminized steel burner and tubes (SST-X), aluminized steel tubes and stainless steel burners (SST-S), or complete stainless steel (SST-Z) units*.

Models

- With a wide range of sizes and models available, choose the ideal superTube to use in your indoor/outdoor wet, damp, harsh space.

| MODEL | TUBES | BURNERS |

| SST-X Series | Aluminized | Aluminized |

| SST-S Series | Aluminized | Stainless-Steel |

| SST-Z Series | Stainless-Steel | Stainless-Steel |

- 50,000 – 250,000 input BTU/HR models

- 20′- 80′ heater lengths

- Built with an EC Motor across the complete product line

- Available in modulating, and single-stage

- Highest mounting options up to 50 ft.

- Factory-installed turbulators and mounted ignitor

- UL Certified

Features

- True modulation adjustment of both air and gas allows precise control of the real-time response to actual heat demand.

- Burner housing design provides improved serviceability with screwless swing-down cabinet service access paired with a clamshell design and access latching system for easy access, which offers time savings with LP conversion and simplifies burner service and maintenance.

- Burner housing design features a refined shape, and an LED illuminating light, and we have skipped the screws again for this model.

- High-efficiency EC Motor with advanced whisper-quiet operation is 2-3x more efficient than standard Shaded Pole or PSC motors.

- Advanced whisper-quiet operation.

- Optimized reflector geometry provides a higher radiant factor and a more uniform heat distribution across the same heating surface.

- Emissive coated radiant tubes are designed to improve the thermal efficiency of infrared heaters.

Built with EC Motor technology

The latest advancement in infrared heating

Intuitive and enhanced operation

- Provides +85% energy efficiencies throughout a full range of operations, in addition to whisper-quiet operation.

- An EC Motor is 2x more efficient than a PSC motor (Permanent Split Capacitor) and 3x more efficient than a Shaded Pole AC motor which is commonly used for infrared tube heaters.

- A constant torque EC Motor leads to more robust and stable combustion through the heaters’ entire range of operation and external pressure changes.

- Schwank has engineered a customized control board (power input 24VDC) built specifically for the modulating superTube Series.

True modulating models

- The custom control board provides real-time optimization of fuel to air ratio for the perfect combustion through communicating with EC Motor and modulating gas valve.

- Eliminates temperature swings by pairing ECM technology with gas valves.

- The heating systems’ service life significantly increases as frequent ON/OFF cycles (cold starts) are reduced.

- Adapt the heat demand in the space, to maintain a consistent comfort level by truly modulating the heat.

Intelligent control technology for heating systems

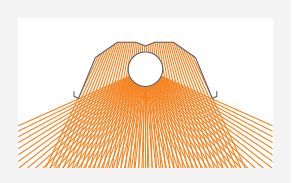

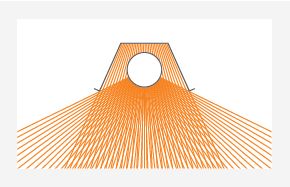

- Optimized reflector geometry provides increased efficiency over conventional reflectors and maximizes heat distribution throughout the entire radiant area.

- Providing a more uniform heat distribution across the same heating surface.

| New reflector | Conventional reflector |

|

|