High-Intensity (Luminous) Heaters

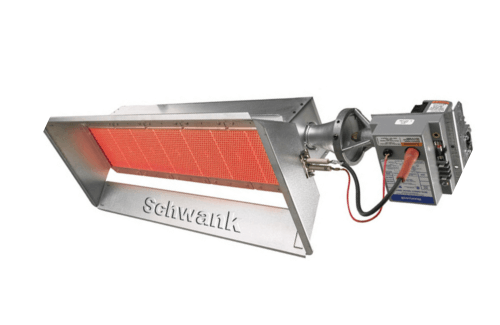

Schwank high-intensity heaters are used in industrial and commercial buildings, logistics facilities, and workshops with medium to high ceilings (up to 180 feet (55m)). They can handle the toughest job for you and get comfort right down to floor level in an instant because the infrared heat waves they emit are absorbed by objects rather than the air. This lowers the cost of operation and the environmental impact. The core component of our infrared gas heaters is the Schwank ceramic tile, invented by the company’s founder Günther Schwank. It is still manufactured by us in Germany.

All three models of Schwank luminous heaters deliver superior performance thanks to our proprietary technology and strict production standards: supraSchwank: 81.2% IR efficiency, primoSchwank: 67.7% IR efficiency, and ecoSchwank: 52% IR efficiency. This performance is verified by independent lab testing to ANSI Z83.6 standard (ANSI Z83.19b/CSA 2.35b) and by DVGW when tested to EN 419-2 standard.

Product Models

Schwank commercial/industrial high-intensity heaters

Advantages

Advantages of Schwank high-intensity infrared heating systems

- Best quality in the industry, our service claims are less than 0.5% of sales

- Uniform, comfortable heat with ceiling heights of up to 180’ (55m)

- Very short ramp up-heating time

- No dust swirls or draught air drafts are produced

- Whisper-quiet operation

- Simple space-saving installation

- Complimentary heating layouts and design support

- Up to 65% energy savings vs. conventional forced-air heating systems

- High return on investment–quick payback, as low as 1 year

- Contributes up to 10 out of 30 LEED points [energy and atmosphere category]

- Zone heating

- Low maintenance [no moving parts]

Technology

Schwank high-intensity heaters explained

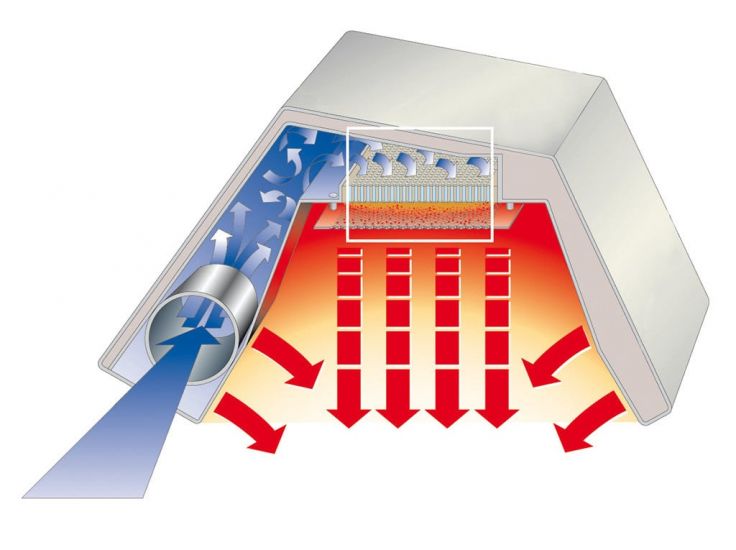

The principle of ceiling-mounted infrared gas heaters

The way high-intensity heaters work just like the sun: the heat rays of the sun travel through the air without heating it and emit their thermal energy only when they fall on contact surfaces.

Our Schwank heaters combine gas (use either natural gas or propane) with air in a mixing chamber, then direct it through the approximately 3,500 combustion channels of the specially developed ceramic tiles. The mixture is ignited just before its outlet. Thanks to the extremely close-knit combustion channels, the ceramic tile is heated to approximately 1800°F (950°C). This results in the formation of radiation energy, which is directed, by means of highly reflective reflectors, to the exact location where it is required. The infrared rays are converted into heat at the point of contact, for example, on our skin but also on the floor, machines, stored goods, and products. Heating, therefore, takes place only where it is required, which is incredibly efficient.

The surfaces absorb the thermal energy and, in turn, re-emit it into the environment. This results in a balanced micro-climate made of air and radiation heat, which is very comfortable for people. The energy costs are reduced significantly and the feeling of comfort is enhanced for the people. As compared to conventional systems, savings generally amount to between 30% to 50%.

It all started with ceramic burner tiles and burners. In 1939, company founder Günther Schwank invented the world’s first gas-operated ceramic burner tile. Today we are still the leader in this technology. Thanks to intensive research & development as well as constant quality controls, Schwank ceramic tiles and gas burners are second to none.

In addition to their high longevity, Schwank ceramic burner tiles are characterized by their industry-leading performance.

The high heat radiation up to 1742°F (950℃) and the unique surface structure of the ceramic tiles make them and the burners suitable for almost any application–from high-power infrared heating systems and de-icing equipment to condensing boilers to overhead heat grills and infrared broilers. Our ceramic tiles ensure maximum performance and efficiency as well as clean, low-emission combustion.

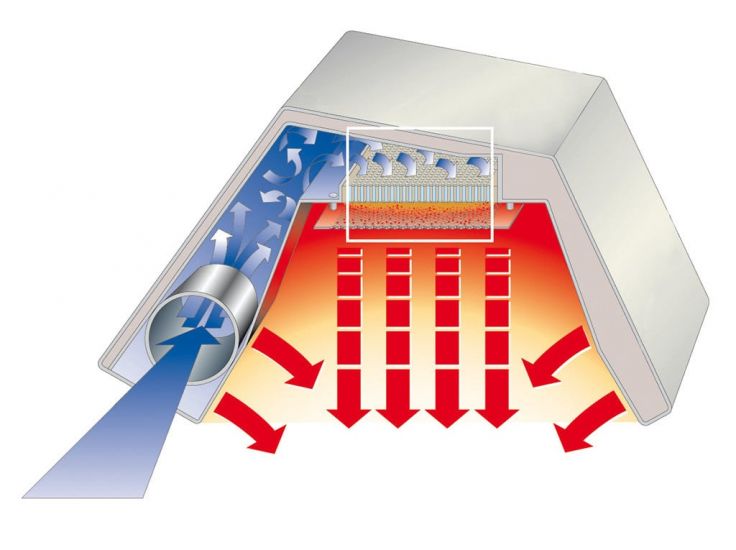

The principle of ceiling-mounted infrared gas heaters

The way high-intensity heaters work just like the sun: the heat rays of the sun travel through the air without heating it and emit their thermal energy only when they fall on contact surfaces.

Our Schwank heaters combine gas (use either natural gas or propane) with air in a mixing chamber, then direct it through the approximately 3,500 combustion channels of the specially developed ceramic tiles. The mixture is ignited just before its outlet. Thanks to the extremely close-knit combustion channels, the ceramic tile is heated to approximately 1800°F (950°C). This results in the formation of radiation energy, which is directed, by means of highly reflective reflectors, to the exact location where it is required. The infrared rays are converted into heat at the point of contact, for example, on our skin but also on the floor, machines, stored goods, and products. Heating, therefore, takes place only where it is required, which is incredibly efficient.

The surfaces absorb the thermal energy and, in turn, re-emit it into the environment. This results in a balanced micro-climate made of air and radiation heat, which is very comfortable for people. The energy costs are reduced significantly and the feeling of comfort is enhanced for the people. As compared to conventional systems, savings generally amount to between 30% to 50%.

In addition to their high longevity, Schwank ceramic burner tiles are characterized by their industry-leading performance.

The high heat radiation up to 1742°F [950℃] and the unique surface structure of the ceramic tiles make them and the burners suitable for almost any application–from high-power infrared heating systems and de-icing equipment to condensing boilers to overhead heat grills and infrared broilers. Our ceramic tiles ensure maximum performance and efficiency as well as clean, low-emission combustion.

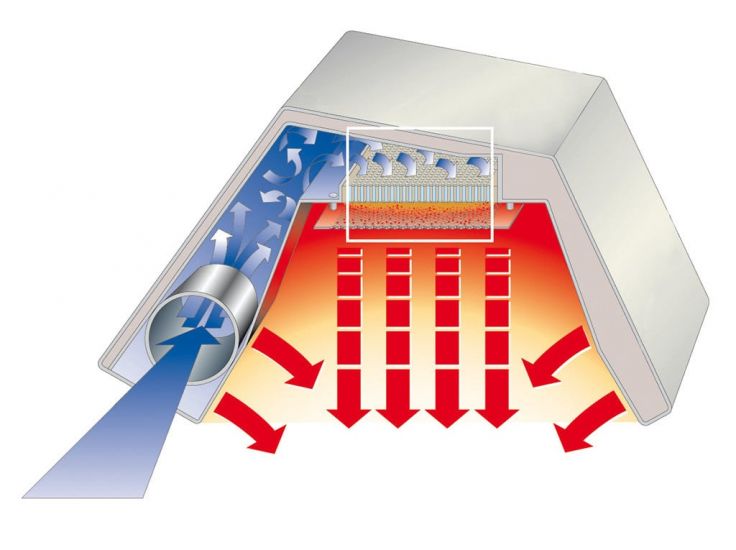

The principle of ceiling-mounted infrared gas heaters

The way high-intensity heaters work just like the sun: the heat rays of the sun travel through the air without heating it and emit their thermal energy only when they fall on contact surfaces.

Our Schwank heaters combine gas (use either natural gas or propane) with air in a mixing chamber, then direct it through the approximately 3,500 combustion channels of the specially developed ceramic tiles. The mixture is ignited just before its outlet. Thanks to the extremely close-knit combustion channels, the ceramic tile is heated to approximately 1800°F (950°C). This results in the formation of radiation energy, which is directed, by means of highly reflective reflectors, to the exact location where it is required. The infrared rays are converted into heat at the point of contact, for example, on our skin but also on the floor, machines, stored goods, and products. Heating, therefore, takes place only where it is required, which is incredibly efficient.

The surfaces absorb the thermal energy and, in turn, re-emit it into the environment. This results in a balanced micro-climate made of air and radiation heat, which is very comfortable for people. The energy costs are reduced significantly and the feeling of comfort is enhanced for the people. As compared to conventional systems, savings generally amount to between 30% to 50%.

In addition to their high longevity, Schwank ceramic burner tiles are characterized by their industry-leading performance.

The high heat radiation up to 1742°F [950℃] and the unique surface structure of the ceramic tiles make them and the burners suitable for almost any application–from high-power infrared heating systems and de-icing equipment to condensing boilers to overhead heat grills and infrared broilers. Our ceramic tiles ensure maximum performance and efficiency as well as clean, low-emission combustion.