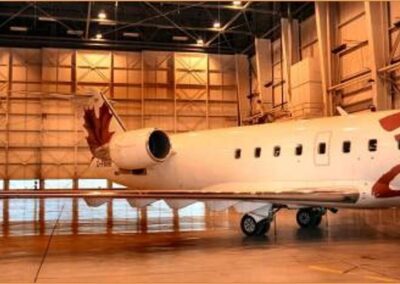

Air Canada, 101 Hanger, Calgary, AB, CAN

Improved comfort with 65% energy and carbon footprint reduction

About the facility

Air Canada, Hangar 101 located in Calgary International Airport, AB, is a 55,000 square-foot aircraft maintenance and operations facility with an average ceiling height of over 64 feet, 1.33 air changes, and an estimated heat loss of 7,200 Btuh.

Air Canada is a full-service airline and the largest provider of scheduled passenger services in the Canadian market, the Canada-U.S. transborder market, and the international market to and from Canada. Together with its regional affiliate Jazz, Air Canada serves over 33 million customers annually and provides direct passenger service to over 170 destinations on five continents. Air Canada is a founding member of Star Alliance and offers the world’s most comprehensive air transportation network.

The issue

Air Canada was aggressively looking for ways to improve and satisfy employee comfort, reduce costs, and conserve energy. Air Canada contracted the services of E-Factor Engineering, an energy contractor specializing in HVAC design and energy retrofits, to complete an operational review of its Calgary aircraft maintenance facilities and to make recommendations to improve comfort while saving energy. Schwank high-intensity heaters were selected, as they provide the most energy-efficient comfort to large industrial facilities, such as aircraft hangars, that have larger energy requirements (Btuh/Sq Ft) due to large infiltration loads, vehicle access requirements, poor insulation, and high ceilings.

Design considerations

- Perimeter mount to stay clear of aircraft.

- Design temp – 4 deg F

- Dimensions 207’ X 244’

- Door size 54’ x 207’

- Door open -1hour 4 x day

- Ceiling height 65’

- Faces N-NW

- Max 1-hour recovery rate

- Heat under the aircraft

Implementation

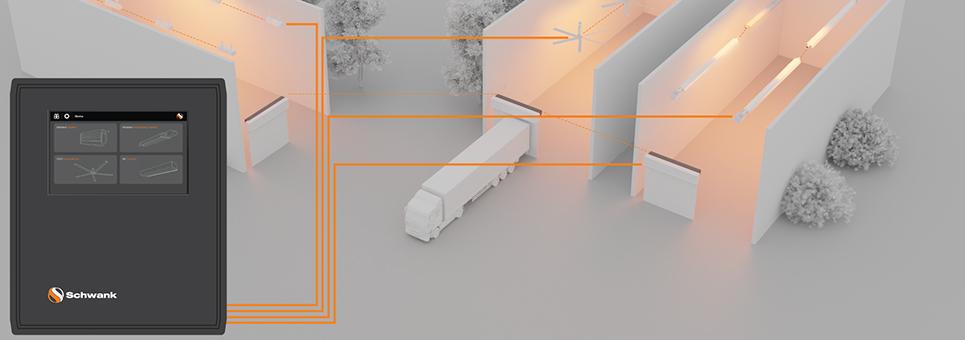

Working in cooperation with E-Factor Engineering, Schwank designed and implemented a major heating system upgrade for Air Canada’s Hanger 101. With 48 supraSchwank high-intensity heaters installed, in addition to a new BMS system, including 5 TruTemp infrared thermostats with automatic setback and recovery capability, replaced the existing1980’s vintage controls.

- 48 SupraSchwank heaters

- Total input 4.2 M BTUH

- Radiant component @ 81%

- 3.4 M radiant BTUH

- Zone control

Results

The installation of high-intensity infrared heaters and revisions to the control strategies save Air Canada over $200,000 in annual energy costs. In the first year alone, fuel costs for Hanger 101 were reduced from $333,000 to $120,000. Air Canada also significantly reduced CO2 emissions from 1,400 tons to 500 tons.

Additional reported benefits included improved comfort, reduced personnel complaints, improved indoor air quality, and extended equipment life with reduced maintenance and low life cycle cost.